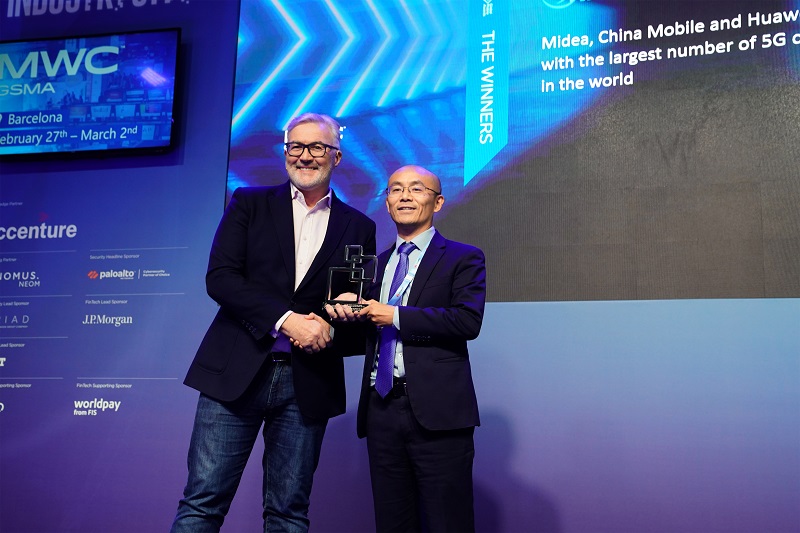

[Barcelona, Spain, February 28, 2023] At the Mobile World Congress (MWC) Barcelona 2023, Midea, China Mobile, and Huawei were named winners of the GLOMO ‘5G Industry Challenge Award in collaboration with the GSMA 5G Hub’ for the 5G fully-connected laundry appliance factory project — the largest of its kind the world has ever seen — that they built together in Jingzhou, a major industrial city in China’s central Hubei province. This award recognizes the extensive application of 5G technologies to smart manufacturing.

Midea, China Mobile, and Huawei Win GSMA GLOMO’s ‘5G Industry Challenge Award’ for a 5G Fully-Connected Factory in Jingzhou

Midea, China Mobile, and Huawei Win GSMA GLOMO’s ‘5G Industry Challenge Award’ for a 5G Fully-Connected Factory in Jingzhou

Midea Group is a Guangdong-based leading electrical appliance manufacturer and plays a pioneering role in bringing 5G to manufacturing. With advanced mobile solutions provided by China Mobile and Huawei, it has built the world’s first 5G fully-connected factory in the home appliance sector. This is the first time that 5G has been fully applied to all industrial production and business operations. In this smart factory, 5G connections have been applied across 15 scenarios and all production links are seamlessly connected through 5G devices. To date, this is the industry’s largest 5G application in industrial campuses, with the largest number of 5G devices used and the most comprehensive use of 5G for production. The project has seen 5G replace complex cabling between machines in the factory, improving workplace safety and allowing machines to operate automatically for higher productivity.

5G networks have become a common infrastructure for automating operations in factories, running deep into core production activities. According to Chen Jun, director of the IT supply chain account department and chief expert on smart manufacturing of Midea Group, the laundry appliance factory in Jingzhou city has used 5G to streamline various production processes. As a result, it takes just 15 seconds for one washing machine to go off the production line, and the number of products directly delivered out to customers is doubled. This slashes warehouse inventory by 50% and save 30% of labor costs required to produce a machine, allowing Midea to improve quality and cost effectiveness while also seeking greener and safer production. “Midea will continue to work with industry partners to accelerate the development of all our 5G fully-connected smart manufacturing factories,” said Chen.

This award will further boost the confidence of the entire industry in expanding 5G digital, intelligent applications from auxiliary to core production processes. It will also representative of 5G playing a more comprehensive role in improving industrial productivity in factories. Zhang Fei, deputy general manager of the government and enterprise division and industrial energy development department of China Mobile, believes that 5G applications are scaling up rapidly from scattered trials to become a new trend of manufacturing development. The parties participating in the project also proposed a guideline in Hubei province based on project experience for other home appliance manufacturers to build 5G fully-connected factories, in an attempt to standardize the solutions for large scale replication. Zhang added that “China Mobile will continue to follow its strategy of working with industry partners to lead the development of digital, intelligent productivity and promote the digital industrial transformation.”

Eric Bao, President of Huawei’s DIS Product Line, said that China Mobile and Huawei were by far the first to implement a list of new technologies to provide full 5G connectivity for the Jingzhou factory. Laser point cloud 3D modeling was first used to support high-precision simulation, allowing indoor 5G private network planning to reach a precision beyond 90%. Multi-band networking was combined with Distributed Massive MIMO to deliver a deterministic uplink capacity of 1 Gbps per 1,000 m2, helping improve AI quality inspection efficiency, the detection rate has been improved by 10%. The world’s first FAB pRRU, designed for smart factories, with internal beam adjusting capability, is also adopted in Jingzhou project, improving the uplink capacity by 10%. “Looking into the future, Huawei will continue to provide innovative indoor network solution to accelerate industrial digitalization and create new value out of 5G businesses,” noted Bao.

MWC Barcelona 2023 runs from February 27 to March 2 in Barcelona, Spain. Huawei showcases its products and solutions at stand 1H50 in Fira Gran Via Hall 1. Together with global operators, industry professionals, and opinion leaders, we dive into topics such as 5G business success, 5.5G opportunities, green development, digital transformation, and our vision of using the GUIDE business blueprint to lay the foundation for 5.5G and build on the success of 5G for even greater prosperity. For more information, please visit: https://carrier.huawei.com/en/events/mwc2023.

PR Archives: Latest, By Company, By Date