the mother of ingenuity

AT&T Field Operations teams are problem solvers – by nature and by trade. But concerns about the COVID-19 pandemic have left us all uneasy and looking for the best way to keep our families safe. And for those field teams, that responsibility extends to protecting both our employees and customers.

“This whole pandemic has made this an unusual time for all of us,” said Daniel Campbell, area manager – Network Services based in Arlington, Texas. “And then when you add the supply shortage to it, it has made it very challenging.”

Over the past few weeks, from homes to hospitals, cleaning supplies have been in short supply. Stores and suppliers are constantly running out as customers clean out their stock as soon as those products become available.

“Product availability was never an issue, it was coming in at first,” Daniel said. “But then it became scarce and trickled to a drip here and there. And it wasn’t like we could go to the store and buy it. That’s important to understand. This isn’t an internal issue. Everyone’s dealing with the same problem.”

Ryan Weaver, a premises technician in Oklahoma City, has experienced that struggle firsthand starting in March, when concerns of COVID-19 really started to spread.

“No one could find any of this stuff in stores,” Ryan said. “I was shopping for my family. But no matter what store we went to, there was nothing out there. I was thankful when I came to work and found out they had found a solution for us.”

“The most unique problem I’ve ever had to solve at AT&T”

The Centers for Disease Control and Prevention (CDC) asserts that hand-washing is the best way to protect against COVID-19. And AT&T, like most other companies, encourages all employees to wash their hands for at least 20 seconds. However, everywhere you turned, the supply of liquid soap was quickly dwindling, as was the supply of the next best, alternative option – hand sanitizer.

“We quickly started to take an inventory of the safety items we had at our shops,” said Cavin Traylor, Network Services manager in Jackson, Miss. “It became obvious we needed to find ways to replenish our stock outside of our normal supply process… so we started brainstorming.”

As quickly as the supply was decreasing, the need to protect employees and customers was increasing. So, Field Ops managers across the country started to do what they do best – troubleshoot.

“When it comes to problem solving, we are good at finding a way to succeed before we say no,” said Charles Thompson, manager – Network Services in Oklahoma City, Oklahoma. His team created small bottles of homemade hand sanitizer, and alcohol spray and purchased multiple bars and bottles of liquid soap for field techs in his area.

“It made me feel a lot better,” said Clint Fowler – a premises technician who received those homemade supplies that Charles and his fellow managers put together. “We keep these bottles in our pockets and we can use them while we’re at a customer’s house and before we eat. It felt great to know they were going above and beyond to help us, our customers and our families.”

Kyle Johnson, a Network Services manager based in Cleburne, Texas, is among the growing list of managers who felt compelled to figure out a solution to help those around him.

“We wanted to do what we could to give our employees items they need – that we all need – to stay safe,” Kyle said. “It’s not just for ourselves. It’s for the colleagues next to us. It’s for the people across the street from us. It’s for the customers down the road from us.”

The bar soap solution

Knowing his field techs needed an immediate solution and drawing on the advice from his leadership team and guidance from the CDC, Kyle developed a way his techs could wash their hands while in the field.

“Bar soap has still been available in stores,” Kyle said. “My wife suggested putting the bar of soap in some pantyhose, like they did when she was in Girl Scouts and then attach that to a water cooler.”

“Everybody is sharing ideas all across the company right now,” Kyle said. Field teams from Texas to Oklahoma and Mississippi to Louisiana are using the Environment, Health & Safety resources to come up with solutions to keep their teams and customers safe.

Homemade hand sanitizer

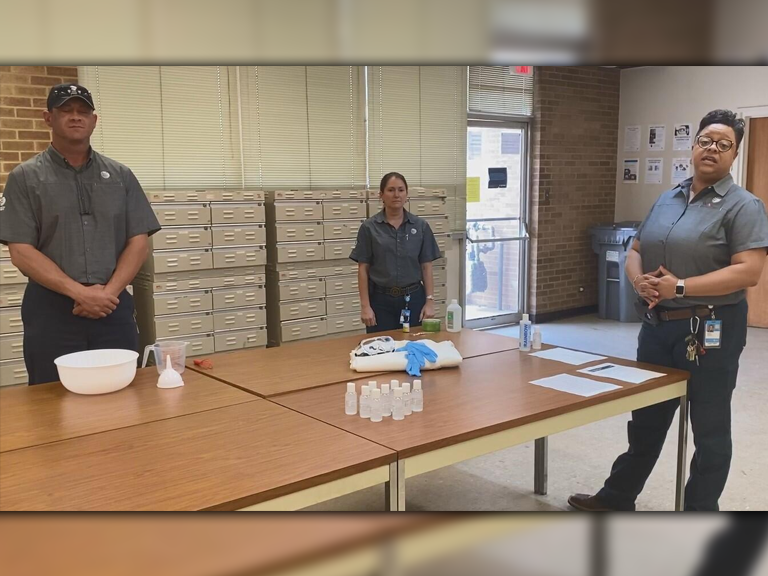

“It’s very important right now,” said Nika Echols, a Network Services manager in Shreveport, Louisiana. Nika along with peers Jennifer Alexander and Dennis Smith got to work on a solution for their teams as they saw hand sanitizer flying off store shelves.

“We wanted to ensure we did what we could as managers to support the safety of our techs in the field,” Nika said. The three managers in Shreveport – much like their colleagues across the country – divided up the shopping duties to find the supplies they would need to create homemade hand sanitizer.

“Each manager volunteered to shop several different stores,” Nika said. “We remained in contact to provide constant updates until we got all the supplies we needed.”

“Our techs were appreciative to get a bottle of hand sanitizer from us that was easy to store in their pockets,” Nika said. “And we’ve heard from customers who were thankful to see the efforts we took to protect them and our employees.”

Many field techs say these homemade products give them a more peace of mind.

“It makes you feel a little better we have something,” said Gen White, a customer services technician based in Kennedale, Texas. “I appreciate that, on top of the work we need to do for customers, they’re also thinking about our safety. We’ll get through this together.”

Togetherness – both in spirit and gesture is what is helping bond our company and community during this pandemic that is driving us apart physically.

“We’re all doing this together,” Kyle said. “We’re pulling together, working together and figuring this out together.”

Unique problems call for unique solutions. This is another example of how AT&T innovates to find those solutions to best serve our employees and customers.

PR Archives: Latest, By Company, By Date